-

Four sides (2000-5500 pcs/hr)

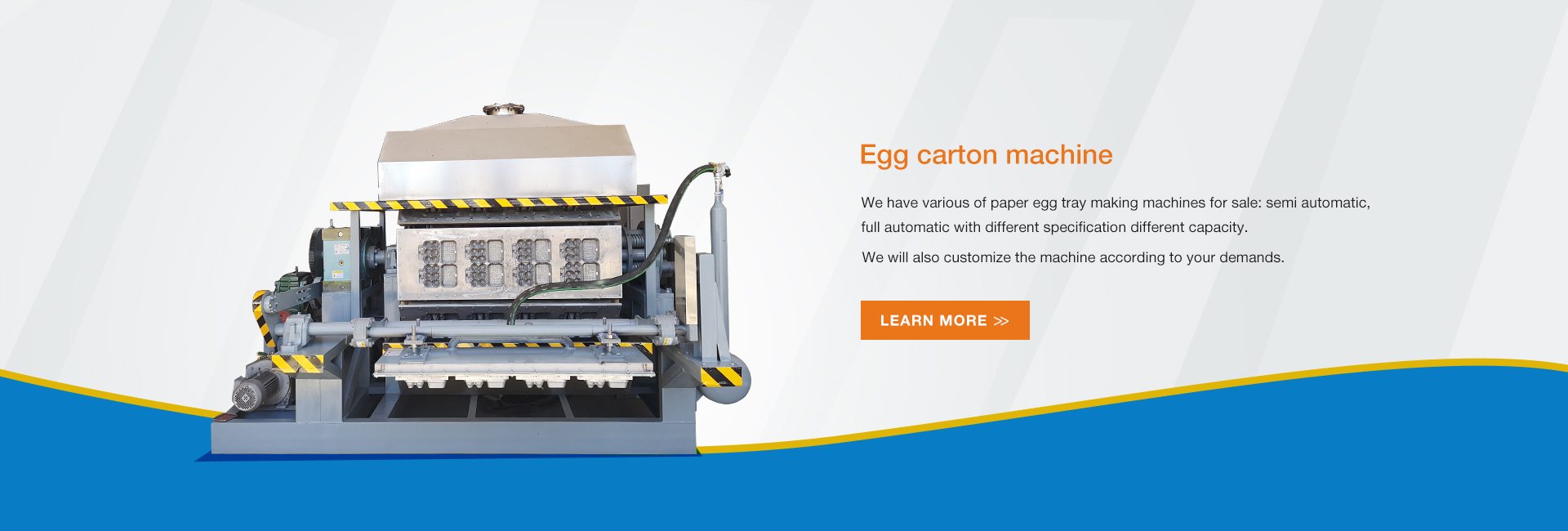

The automatic rotary paper egg tray machine uses waste paper as raw material and it can produce different kinds of products according to your requirements, such as egg trays/dishes, egg cartons/boxes, fruit trays, coffee cup trays, wine bottle trays, industrial packages, electrical lining packing trays and so on. The different final products are decided by your market choice. The egg tray machine moulds can be designed and made as customers’ requirement with samples.

-

Paper Pulp Molding Machine One side (600-1700 pcs/hr)

This equipment is a flip-type molding machine, which is composed of molding templates, transfer templates, worm reducers, motors, intelligent control electrical appliances, cylinders, solenoid valves and other components. The worm reducer is driven by the transmission motor to make the equipment template run at 90 degrees. This equipment was independently developed and manufactured by our company in 2008 and is now widely used in the egg tray and paper tray industries.

-

Eight sides (4000-10500 pcs/hr)

The automatic rotary paper tray production line is composed of a pulping system, a forming system, a drying system and a packing system. Pulping: It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays. Molding: The process is that using negative pressure and vacuum absorption turn the slurry to egg trays. You can make egg trays, egg boxes, apple trays and so on with the egg tray machines by changing different moulds. Drying: It basically involves drying the wet semi-finished products by using egg tray drying line. Good drying process can lead to minimal losses of poorly-formed trays. There are metal and brick egg tray drying line.

-

Twelve sides (5500-7500 pcs/hr)

The automatic rotary paper tray production line is composed of a pulping system, a forming system, a drying system and a stacking system. It is used to produce egg trays, fruit trays and other products. Using waste carton paper, waste newspapers, book papers, scraps and other waste paper as raw materials, through hydraulic disintegration, filtration, water injection and other processes to prepare a certain concentration of slurry, through the molding system on the special metal mold through vacuum adsorption A wet blank is formed, then dried by a dryer and stacked.

-

Industrial Packaging Production Line

The automatic reciprocating paper tray production line is composed of a pulping system, a forming system, a drying system and a stacking system. It is used to produce fruit trays, wine bottle trays, electrial lining packing trays and other products. Using waste carton paper, waste newspapers, book papers, scraps and other waste paper as raw materials, through hydraulic disintegration, filtration, water injection and other processes to prepare a certain concentration of slurry, through the molding system on the special metal mold through vacuum adsorption A wet blank is formed, then dried by a dryer and stacked.

-

Paper Tray Production Line Forming System

Forming process of paper tray forming machine The forming system is the most important link in the entire production process. Paper tray forming machine is a device for producing paper tray. With the wide application of paper trays, many paper tray manufacturers have emerged at home and abroad. The selection of paper tray forming machines needs to be based on the forming process adopted by the paper tray manufacturers. 1.Paper tray forming machine—vacuum suction forming machine, this for... -

Paper Tray Production Line Pulping System

Pulper The main function is breaking waste paper into required pulp. The working method: decomposing waste paper to pulp by hydraulic and mechanical reamer. Advantages 1. Energy saving 2. Flexible production 3. Low mould input 4. Easy operation and maintenance Parameters of Hydrapulper Overview of high-consistency hydraulic pulper: high-consistency hydraulic pulper is one of the equipments in waste paper deinking pulp. Its function is not only to disintegrate waste paper into p... -

Paper Tray Production Line Drying System

Natural drying Advantages:Low cost Disadvantages: (1)Large area (2)susceptible to weather (3)Low efficiency, suitable for small capacity equipment Brick dryer Advantages: (1)Low cost (2)Not affected by weather (3)Efficient Disadvantages: Large area Natural drying: mainly rely on natural weather (sunshine, wind) to dry naturally. Components of the brick dryer: standard bricks, refractory bricks, cement boards. The equipment components are composed of: drive system... -

Pulp Molding Tableware Production Line

video Your browser does not support video tags. Tableawre The rotary pulp tableware forming equipment is independently designed and developed by our company. The raw materials can use plant fibers, such as: bagasse, wheat grass, reed, bamboo and other plant fibers that can be regenerated every year. The equipment can be used to produce lunch boxes, plates, etc. It can be completely degraded, taken from nature and attributed to na... -

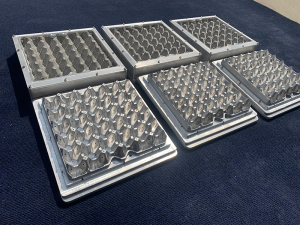

Pulp Molding Molds

Mould Environmental protection pulp industrial packaging mold workshop – the company has 3 professional industrial package mold designers and more than 20 technicians. The designers have been engaged in the research, design and production of paper tray molds in the Pearl River Delta of Guangdong for many years; they have rich experience in making industrial packaging paper tray molds;The packaging molds designed and produced for household appliances, handicrafts, porcelain and othe...